The Daily Free Press recounts the HUBWeek event in which Center Director Bruce Rosen and medical illustrator Danny Quirk spoke about the intersectionality of human anatomy and visual art.

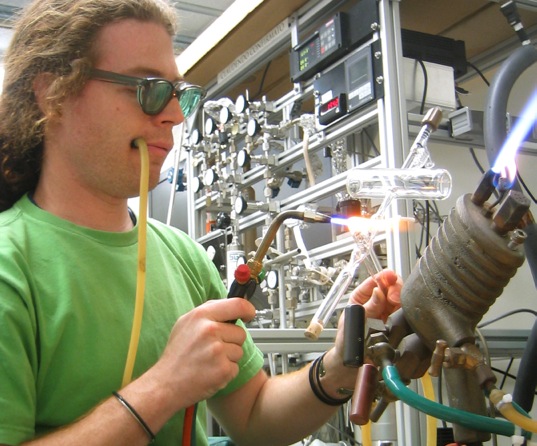

The (Nearly) Lost Art Of Scientific Glassblowing

Scientific glassblowers, like streetcar conductors and silent movie organists, are a vanishing breed.

Scientific glassblowers, like streetcar conductors and silent movie organists, are a vanishing breed.

“There are very few left in the world,” said Matt Rosen, director of the Low-Field Imaging Laboratory at the MGH Martinos Center for Biomedical Imaging. “And even fewer who can manufacture the glass optical pumping cells I use in gas hyperpolarization systems.”

Fortunately, particularly for those who depend on such things, Rosen is working to keep the tradition alive, creating glass equipment for his research and even teaching others the finer points of the practice.

Scientific glassblowing has a long and storied history. Without it we might never have known, for example, Galileo’s thermometer or Edison’s light bulb. But what is it exactly? And how does it differ from, well, regular glassblowing?

Broadly speaking, it is the process of forming molten glass into equipment by blowing short puffs of air into it and shaping it before it cools and hardens. Scientists today use it to make all kinds of apparatus, from beakers and test tubes to very clean ultra-high-vacuum systems.

In many cases glass is the ideal material for these, Rosen said—not least, in experiments dealing with reactive compounds such as alkali metals.

For more than 20 years Rosen has been using laser optical pumping for hyperpolarization of nuclear spins (in gaseous helium, for example) and this work typically requires an alkali atom as an intermediary.

“These atoms are very reactive,” he said. “In fact, they are explosive in contact with water vapor. So these systems need to be super clean, and made of an alkali-resistant material. Glass is one of the very few materials that have these properties and can handle operation at very high pressure.”

Glassblowing of any sort requires a steady hand and an understanding eye but scientific glassblowing adds another layer of complexity to the kind you might see in crafts fairs or on Home & Garden TV. While the latter generally involves fashioning hanging ornaments, for example, from solid glass rod, the former often relies on hollow glass tubing. And working with hollow tubing—to no one’s surprise—can be a great deal more challenging.

Rosen learned the craft when he was a graduate student at the University of Michigan, studying with a master glassblower named Roy Wentz. From Wentz he learned the basics—how to cut, weld, resize and bend tubing, how to make glass-to-metal seals and vacuum pull-offs, and so on—that would help in fabricating the systems he was using in his graduate research.

When he arrived at Harvard in 2001, as a postdoctoral fellow in the Harvard-Smithsonian Center for Astrophysics, he found there was no one locally who could help make optical pumping cells and manifolds for his ongoing work. So, armed with his training by the master glassblower, he decided to make them himself.

It wasn’t long before students, postdocs and others saw what he was doing and, wanting to learn how they could fashion the glass systems they needed for their own research, started seeking out his help. Before he knew it he was teaching a scientific glassblowing workshop at Harvard, instructing experimentalists in the atomic physics community about the nearly lost art. He still does this today. A new generation of researchers is now carrying the glassblowing torch.

They are finding it is a very worthwhile endeavor. Scientific glassblowing is challenging and even humbling, Rosen said, but ultimately tremendously satisfying. “It takes endless practice to make things look good. But it is a beautiful skill once you learn it. It is a very creative art form, and also very technically demanding. That is an interesting balance, much like playing a musical instrument.”

And like playing an instrument, “mastery takes a lifetime,” he said.

Those interested in discussing the use of fabricated glass for their experiments can contact Rosen in the Low-Field Imaging Laboratory at the Martinos Center.